Transformer Services

Turnkey Transformer Change-out Solutions

Whether you need emergency transformer repair or you have a scheduled GSU, AUX, ESS, GCB or CT change-out project planned, your electrical bus duct system will be impacted. A key aspect of the overall project success will depend on the quality, capabilities, and efficiency of your electrical bus duct contractor. A variance in elevation, flange layout, orientation of contact surfaces, and phase spacing, are just a few obstacles that could easily cause major delays if not foreseen and properly planned for; prior to beginning onsite activities.

EBI works closely with our clients to ensure a collaborative approach that yields safe, sustainable and measurable results. Pre-outage planning and bus duct condition assessment is essential to ensure your transformer change-out project is completed successfully, safely and on schedule.

From project management and planning, to fabrication and execution of onsite services, EBI is the contractor of choice for turnkey transformer change-outs. No matter how simple or extensive your transformer change-out project is; whether it is planned far in advance or is an emergency, we will put our experience to work for you and give you peace of mind. If you have change-out project coming up, take advantage of scheduling a webinar or lunch and learn with members of our technical team to discuss how we can put our expertise to work for you to guarantee success on your future projects.

Our Core Competencies Include:

- GSU, AUX, ESS, GCB & CT Installation & Change-Outs

- PT/SA/VT Cubicle Installation & Change-Outs

- 24/7 Emergency Response

- Bus Duct Demolition, Removal & Re-Installation

- Replacement Termination Enclosures

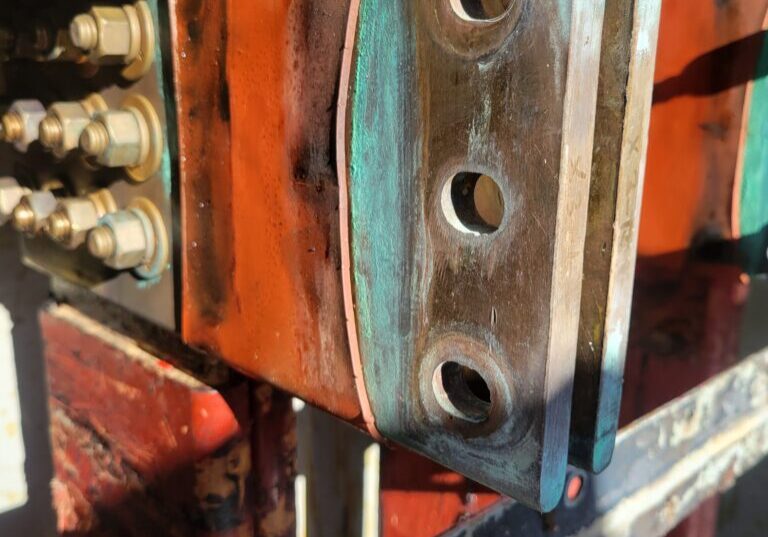

- Replacement Adapter Bars & Flex Links

- Replacement Isolation GP03 / G10 & Hardware

- Contingency Planning

- Transformer Replacement

- Transformer Services

- Testing

- Fabrication

- 3D Modeling

Downloads

Related Projects

Experience a Failure?

24/7/365 Emergency Services

EBI’s State-of-the-Art

R3 Mobile

Fabrication Unit

EBI’s Mobile R3 Fabrication Unit; is a 53-foot, all-in-one, self-powered, semi-trailer that houses all the machining and tooling required to fabricate, refurbish and completely repair electrical isophase, segregated and non-segregated bus duct systems and related components in the field.

Our immensely talented fabricators, coupled with the onsite proximity of the R3 offers increased efficiency and enhances communication between field technicians, machinists, engineers, and plant personnel while allowing ‘As-Found’ issues to be seamlessly added to EBI’s project scope. The 24/7/365 availability of the R3 has also proven to be invaluable for emergency projects that involve a transformer or bus duct failure, particularly since projects of this nature are largely based on discovery and the need for rapid, accurate repair and expedited fabrication of replacement parts is critical.

Whether you need to repair, refurbish or completely replace your electrical bus duct system, EBI’s state-of-the-art R3 contingency unit is fully equipped to handle all of your needs. We have experience with all major OEMs, both current and obsolete.

With unprecedented efficiency and 24/7/365 availability, we’ve got you covered.