Professional Services

Enhance Plant Performance

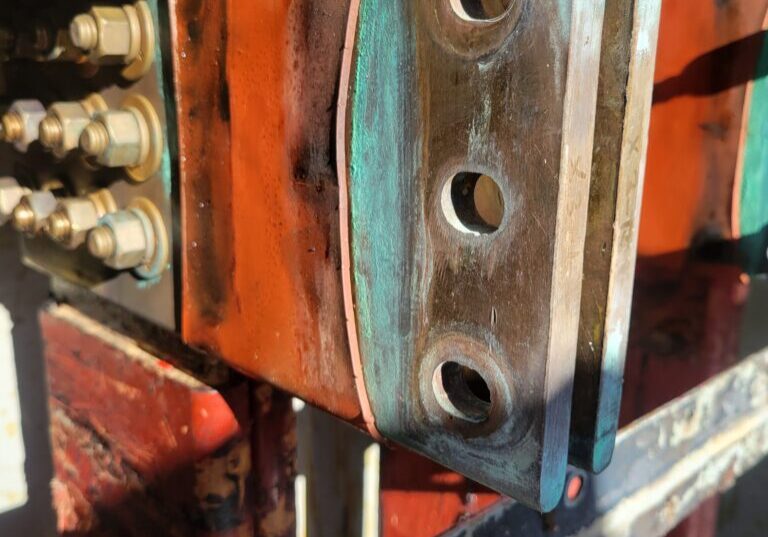

Clients regularly turn to EBI to be their long-term partner for customized professional services. Whatever your needs, electrical asset life extension and bus duct maintenance, work-package or SOW development, project or contingency planning, EBI has flexible resources to meet your specific needs. Our priority is supplying solutions for you that do more than work; they make your work easier, more efficient, safer, and ultimately, more productive. This enables your team to focus on other balance of plant outage objectives.

In addition, EBI is uniquely positioned to assist with the conversion of decommissioned power plants into viable energy sources to meet the explosive demand for data center power. Our team brings decades of experience in revitalizing aging infrastructure to support the evolving needs of digital infrastructure expansion.

Our Core Competencies Include:

- Electrical Asset Life Extension Solutions

- Contingency Plan Development, Oversight & Execution

- Data Center Construction Services

- Nuclear Plant Maintenance

- Power Generation Repair Services

- Power Plant Outage Support

- Outage Maintenance

- Program Management Oversight

- Field Safety Representatives

- Project Planning

- Certified Weld Inspectors (CWI)

- Owners Representative Oversight

Contingency Plan Development

Knowledge and data transfer are two of the biggest challenges utilities face when employees retire. Incoming replacement personnel often have to go on a hunting expedition to find and collect system critical component data before they can start to develop their power plant maintenance outage plans and/or operation schedules. If and when they locate the necessary documentation, often times crucial information is missing, illegible, or inaccurate. Add to these issues the fact that lead-times on parts and materials have been significantly extended due to decreased production from the pandemic. These pitfalls result in inaccurate RFQs, unforeseen Change Orders and major project delays. Worse yet, if your plant encounters an unplanned outage or failure, these pitfalls will impact how quickly you can get back online.

RISK 1 - Unpredictable Supply Chain

Current lead-times are longer than ever before for electrical bus duct materials, parts and replacement components. Are you prepared for significantly longer lead-times if you do not have the appropriate spare parts on hand?

RISK 2 - Missing or Inaccurate Documentation

Missing, outdated or inaccurate system documentation can cause major delays and inaccuracies during the RFQ process. It can also significantly impact an outage schedule because unforeseen changes to the scope of work have to be addressed during the outage; ultimately impacting the bottom line. Do you know if your prints, drawings, BOM and other necessary documentation is accurate? Do you have the information you need to properly identify and procure the necessary parts and materials needed prior to your outage?

RISK 3 - Incomplete Contingency Plan

Many contingency plans lack the critical details needed if an unexpected failure occurs. Often times, a like-for-like exchange does not go according to plan and onsite plant personnel does not know who to call; causing increased downtime that impacts the bottom line.