Summary:

When an unexpected bushing failure occurred, this plant relied on EBI for demo, custom fabrication of replacement doghouses and IPB sections, cryogenic cleaning, and the supply of spare parts necessary to accommodate the transformer change-out activities to get the Unit back up and running.

Scope of Work:

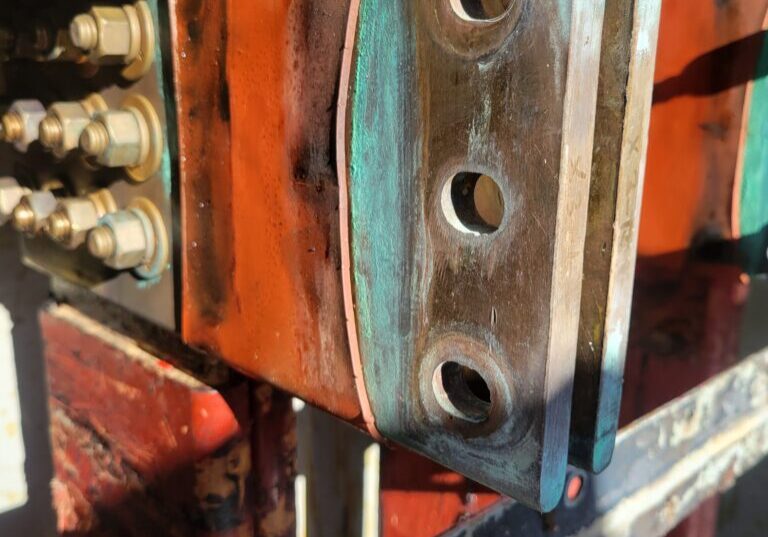

- Removed sections of bus from blast wall to the GSU

- Cryogenically cleaned bus from GCB to UAT

- Modified bus and installed bolted covers at the UAT

- HI-POT testing AF and AL from the GCB toward the GSU

- Assisted in alignment of new transformer

- Removed braids from GCB on GSU side, cleaned and reinstalled

- Fabricated three new dog houses and IPB sections

- Installed new support steel

- Installed new dog houses and IPB sections

- Silver soldering of draw leads on high side

- Supplied braids and hardware to connect IPB to GSU

If your power plant experiences a transformer, bushing, or bus duct failure, rely on EBI's extensive bus duct expertise. to get you back online. Our Rapid Response team specializes in emergent/quick turn transformer change-outs and onsite fabrication of replacement components with our state-of-the-art R3 mobile factory. Whether you need a technical representative onsite ASAP to assess the damage and develop a repair plan, require emergent fabrication of replacement components (both current and obsolete), or need a full turnkey solution to get you back online as safely, quickly, and efficiently as possible, you can rely on EBI’s team of industry experts.

Project Details

| Plant Type: | Natural Gas |

| Plant Size: | 827 MW |

| Plant Location: | Texas |

| EBI Job # | 3450 |

Testimonial

"Led by example and was able to keep crew motivated and working."

Tom A.

Project Manager