Summary:

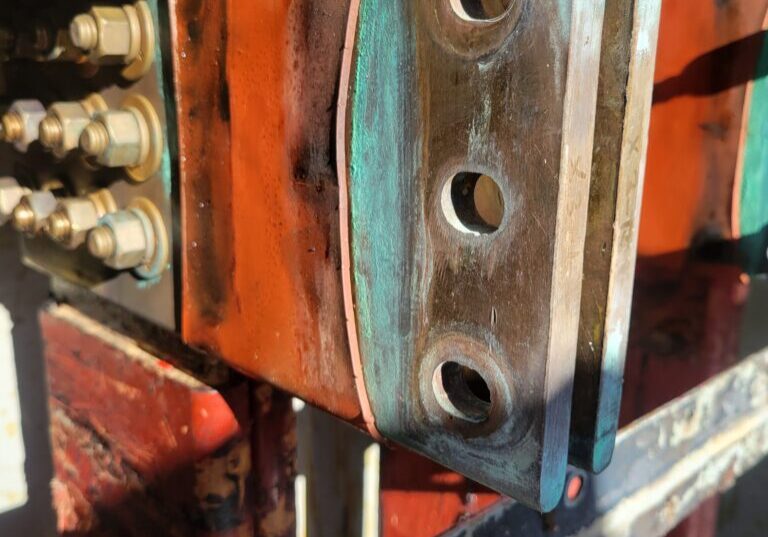

EBI mobilized to this coal fired generating station to perform an offline inspection and testing of the Non-Segregated (NSB) runs and associated components on Unit UAT 11C. While onsite, EBI’s scope was expanded to include additional NSB testing and inspection on Units UAT 11A and UAT 11B. EBI discovered the system was suffering from lack of proper, routine planned maintenance; leading to arch damage, tracking, corrosion, and deterioration.

EBI’s team performed the necessary inspection, in-field silver plating, refurbishment, and necessary bus bar repairs; bringing this power plant’s non-seg bus system back to like new condition.

Scope of Work:

- Found compromised insulation on the non-seg bus bars from the doghouse to the blast wall

- Removed the existing insulation and replaced with new heat shrink insulation

- Performed in-field silver plating and refurbishment as necessary

- Removed, sealed, and re-installed the insulator supports from the doghouse to the blast wall

- Refurbished the bus bars by performing weld repairs and blending smooth

- Installed new gasket and hardware as needed to ensure a proper seal

- Fabricated and installed a new access cover

If your non-seg bus system has not been inspected by qualified personnel in the last 18-24 months, there’s a good chance that similar conditions exist. Routine maintenance best practices and inspection, performed by qualified and trained personnel, is the most effective way to maintain the health of these system critical electrical components and mitigate opportunities for a forced outage within your power generation fleet.

Project Details

| Plant Type: | Coal |

| Plant Size: | 2,600 MW |

| Plant Location: | Indiana |

| EBI Job # | 3317/3338/3339 |

Testimonial

"These guys were very professional."

Brian H.

Plant System Owner Principal