Summary:

Does your existing isophase bus duct system lack accessibility for easy inspection and planned maintenance? If so, what’s hiding within could put your entire power generation system at risk of failure. In this premier project, we feature a power plant that opted to extend the life of their system critical electrical assets by having EBI perform the necessary inspection, cryogenic cleaning, and recommendations for future repairs that will keep their system running at peak performance. EBI’s aftermarket inspection windows can be installed in any OEM bus design and provides easy, repeatable access to the internal area of your isolated phase bus system.

Scope of Work:

- Provided oversight for building the scaffolding

- Supplied a subcontractor and provided oversight for lead paint abatement activities

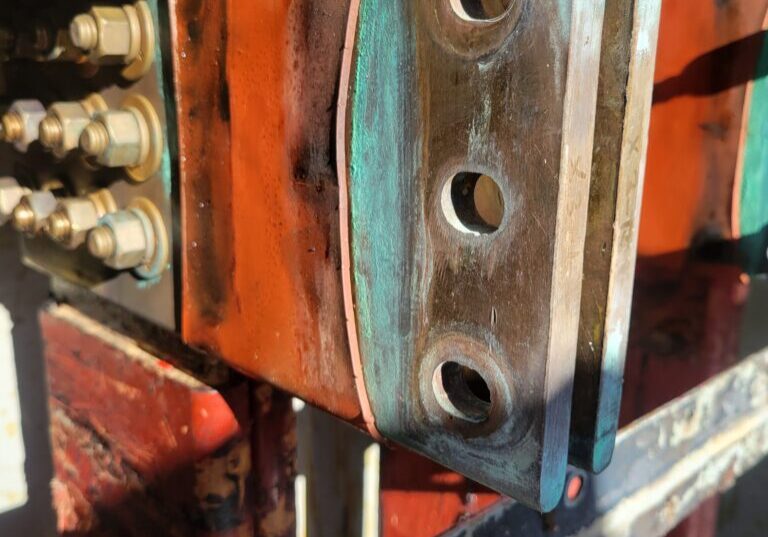

- Cut access into the IPB to cryogenically clean and inspect the system

- Installed 33 of EBI’s propriety welded access ports

- Opened, cleaned and inspected the Unit’s reversal switches and PT connections

- Cleaned and inspected the generator connection and seal offs

If your bus system lacks accessibility or has not been inspected by qualified personnel in the last 18-24 months, there’s a good chance that similar conditions exist. Routine maintenance best practices and inspection, performed by qualified and trained personnel, like EBI, is the most effective way to maintain the health of these system critical electrical components and mitigate opportunities for a forced outage within your fleet. If you have an upcoming maintenance outage planned, have critical projects that require bus duct expertise, have fabrication needs, or would like to learn more about saving money with EBI’s fleet wide maintenance and service agreement, contact us today.

Project Details

| Plant Type: | Pumped Hydro Storage |

| Plant Size: | 1,168 MW |

| Plant Location: | Massachusetts |

| EBI Job # | 3273 |

Testimonial

"Strongest Assets: Attention to detail and professionalism."

Y.G.

Senior Operations Manager