Summary:

This premier project highlights EBI’s emergency fabrication and refurbishment services for unique, obsolete, or complex parts. During the initial walk-down failure analysis, our team of technical experts discovered a compromised HV firestop/seal off bushing that was damaged beyond repair. EBI utilized its in-house fabrication capabilities to reverse engineer a replacement; expediting the plant’s ability to return online.

Scope of Work:

- Emergency inspection due to a fault on Unit 1 CTG, A Phase

- Testing of IPB determined location of ground faults and tripped relays

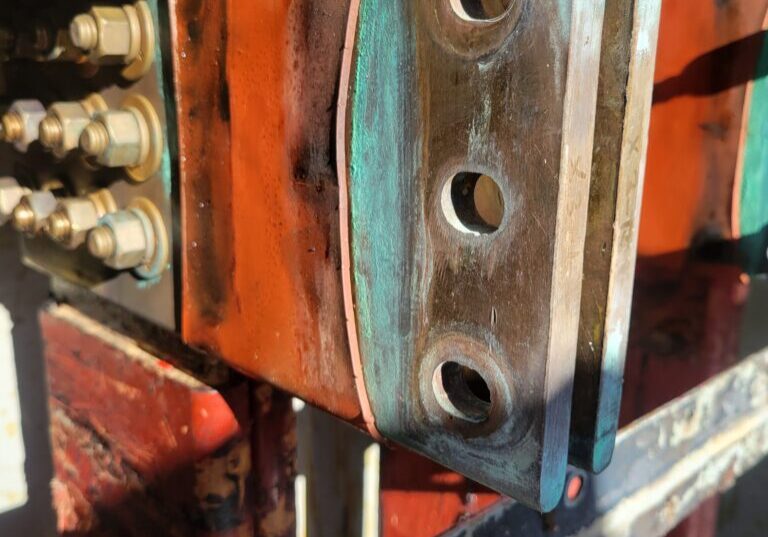

- Water intrusion was found along with a compromised seal off bushing

- Cut and removed a section of the bus duct and returned it to the EBI’s fabrication facility to be rebuilt

- Field crew cut in and welded 10 of EBI’s proprietary inspection ports on the outside section of the A Phase bus duct

- Cryogenically cleaned and hand wiped all 10 insulators

- Supplied and installed new bus duct section and seal off bushing

- Set, fit up, and welded the conductors and enclosures back together

- Ran a passing Hi-Pot test

- Reinstalled the braids at the UAT and GSU with new hardware

- Reinstalled boots at both UAT and GSU

Whether you have an upcoming transformer change-out project planned, require bus duct expertise for critical projects, need custom fabrication, or if you experience an emergency failure, rely on EBI’s extensive bus duct expertise to get you back online as quickly and safely as possible! If you would like more information or to request a quote, please contact us.

Project Details

| Plant Type: | Natural Gas |

| Plant Size: | 730 MW |

| Plant Location: | Wisconsin |

| EBI Job # | 3266/3268/3269 |

Testimonial

"Installation of bus duct went great. EBI team stayed engaged with site personnel and provided timely updates. Crew displayed a wealth of knowledge that led to them finding the actual problem. crew maintained a safe environment during the entire evolution as well as keeping their work area clear of all hazards."

K.G.

Maintenance Manager