Summary:

EBI was called in to perform an emergent inspection on this plant’s isolated phase bus (IPB) system after thermal hot spots were detected. Our root cause analysis revealed the issue as inadequate expansion bellows causing localized heating and reliability risks.

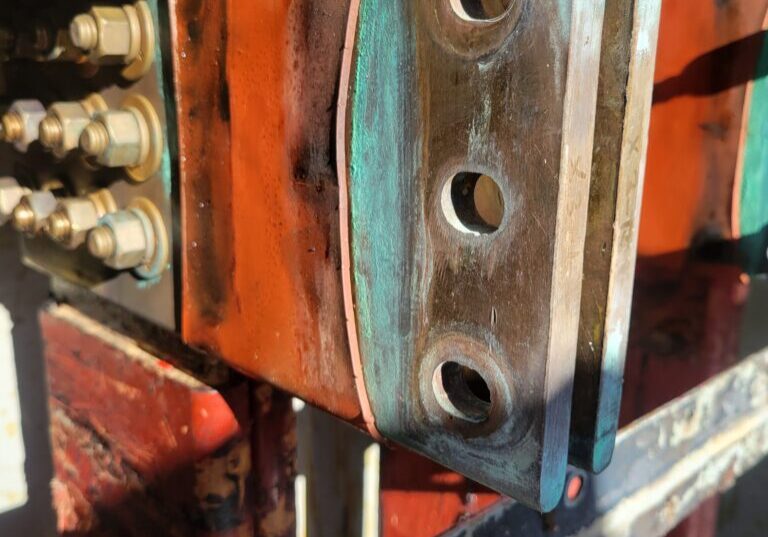

Over time, IPB bellows can degrade due to age, thermal cycling, or misalignment. When separation occurs, it not only compromises alignment but also creates pathways for moisture and contaminants to enter the enclosure, further accelerating system deterioration.

Scope of Work:

For this project, EBI’s team cut, fabricated, and replaced expansion bellows on the Unit 3 STG IPB run across all three phases. Each replacement was precision-fit to the system, restoring alignment, sealing out contaminants, and protecting against future failures.

The result? A system brought back to peak condition with extended life expectancy and improved reliability.

Are your IPB bellows warning you of trouble ahead?

-

Overheating bolts on support steel

-

Hot spots on bus duct

-

Elevated currents on ground cables

-

Water intrusion inside the bus

These aren’t just nuisance issues, they’re early warning signs of compromised bellows that can lead to costly, unplanned outages. If you’re seeing the red flags, EBI can help you get ahead of the problem with engineered repair and replacement solutions designed to keep your bus systems running safely and reliably. Give us a call to day at 877-297-0616.

Project Details

| Plant Type: | Natural Gas |

| Plant Size: | 1,256 MW |

| Plant Location: | Illinois |

| EBI Job # | 4021 |

Testimonial

"Guys are hard workers."

Nick L.

Lead I&C