EBI’s Aftermarket Electrical System Enhancements

Since 1974, power generation and utility clients across North American and beyond, have turned to EBI’s nearly 50 years of extensive bus duct expertise to extend the life of their system critical electrical assets in order to keep their systems running at peak performance. EBI’s fleet wide system enhancements feature after-market solutions to proactively address and combat common bus duct system issues. These issues include inadequate design, condensation, lack of accessibility to perform routine maintenance, and degraded components. EBI’s fleet wide system enhancements, coupled with a routine preventative maintenance plan, have proven to dramatically prolong existing metal enclosed bus systems and mitigate forced outages.

Welded Inspection Ports

Proactive preventative maintenance, per industry standards, is essential to any asset life extension program. However, many isophase bus duct systems lack accessibility inside the enclosure for easy inspection and planned maintenance, endangering the entire power generation system. Commonly found issues include cracked insulators, water intrusion, debris, dust/dirt build up, and loose, incorrect, or missing hardware. EBl’s aftermarket welded inspection ports are designed specifically for isophase applications and can be installed in any OEM bus design. They provide easy access to the internal isolated phase bus enclosure and insulators for necessary visual inspection and cleaning to maintain the health of your system critical electrical components and mitigate opportunities for a forced outage.

Dry Air Pressurization Systems

Outdoor bus systems that are subject to drastic temperature fluctuations due to climate location, thermal cycling, de-energized/re-energized due to an outage, and/or systems that are not properly sealed can suffer significate condensation build up and water intrusion, which left undetected, can increase chances for a catastrophic failure. EBI’s after-market dry air pressurization systems provide slightly positive air flow to replace the moist air inside the enclosure and is the industry standard and preferred method to combat condensation that can form in isophase bus systems.

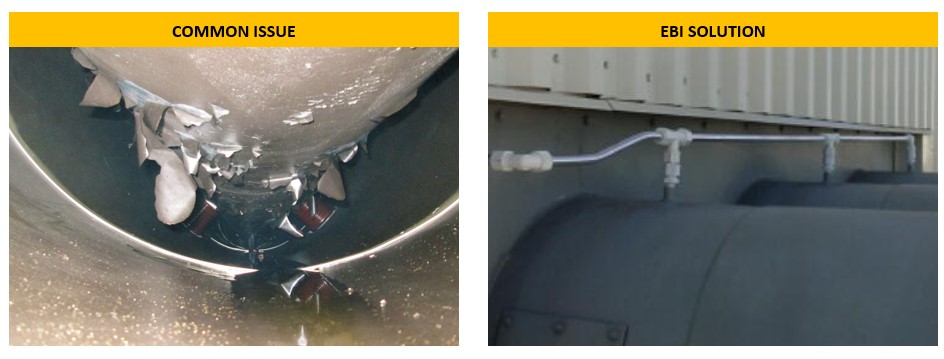

Drainage Solutions

In outdoor bus installations subject to drastic climate conditions, drain plugs are commonly used at the low end of the bus run to allow excess condensation to escape from the enclosure. Drain plugs can be a simple, manually operated drain or contain a valve allowing liquid to escape while holding air within the enclosure. They are commonly used on isophase, non-seg, and segregated bus duct systems.

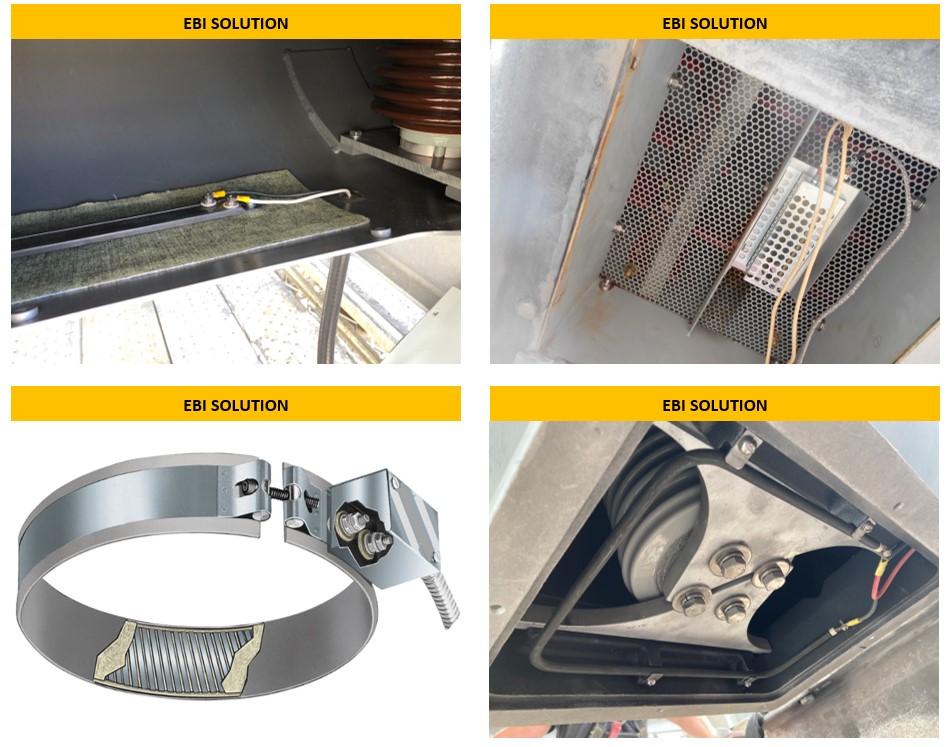

Heaters

When a bus system is de-energized or runs for a period and shuts down in cycles, heaters should be turned on before the system is re-energized to dry any condensation. There are several different styles of heaters. Strip heaters are typically used in non-segregated and segregated bus designs but can also be found in IPB. The number of heaters used and spacing of the heaters in the enclosure are based on how much area needs condensation control and the output of heat from the heater. Insulator heaters are sometimes used in isolated phase bus and are installed around the top of porcelain insulators or mounted to inspection ports. There are various shapes and designs that are specific to each bus OEM. Although not the best method of controlling condensation within the bus, they are effective in keeping insulators dry.

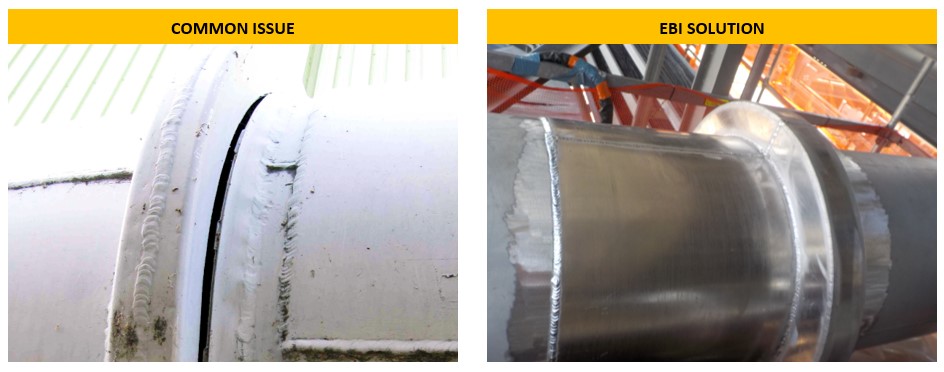

Expansion Bellows

Expansion bellows are an essential part of the bus duct system. They are designed to compensate for expansion, movement, and vibrations that occur during normal operation. However, the increased frequency and level of cycling caused by the surge of intermittent renewable generation have significantly shortened the typical lifespan of many critical components, including metal expansion bellows. The old original metal bellows will experience thermal fatigue, begin to crack, and will eventually begin to pull away from the enclosure leaving the bus subject to foreign material intrusion. EBI’s proprietary 3-piece expansion bellow can easily be installed on existing isophase bus systems without modifications to the conductor.

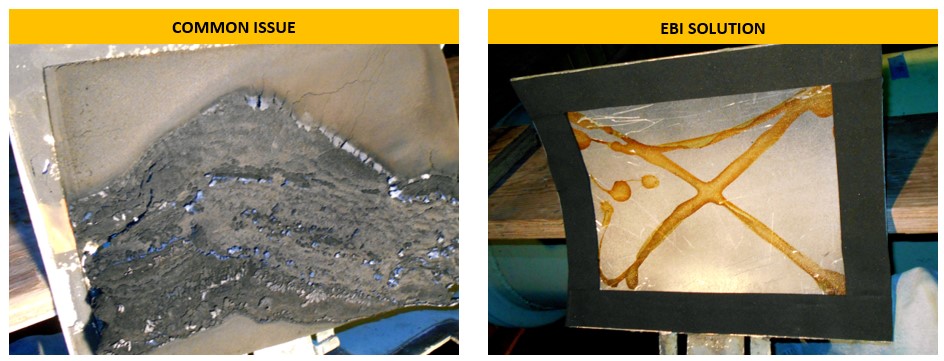

Gasket

When your plant’s electrical bus duct components become degraded, even something as simple as gasketing, can easily wreak havoc on the system if not identified and properly corrected in a timely manner. Gasket should be replaced as needed in order to properly seal the system and mitigate opportunities for moisture and foreign material intrusion.

If you have an upcoming maintenance outage planned, have critical projects that require bus duct expertise, have fabrication needs, or would like to learn more about extending the life of your system critical electrical components with EBI’s fleet wide maintenance and service agreement to ensure continuity fleet wide, give EBI a call at 877-297-0616 or request a quote at [email protected].