EXCLUSIVE CONTENT

Brief Summary:

The purpose of this article is to educate power plant operators and maintenance personnel on the importance of metal enclosed electrical bus, an often-overlooked system critical component spanning from the generator to the main transformer, carrying the system’s full current. Metal enclosed bus is stand-alone, custom made for each plant, and non-redundant. When a failure occurs; the entire energy producing system shuts down until this critical component and its appendices are repaired or replaced.

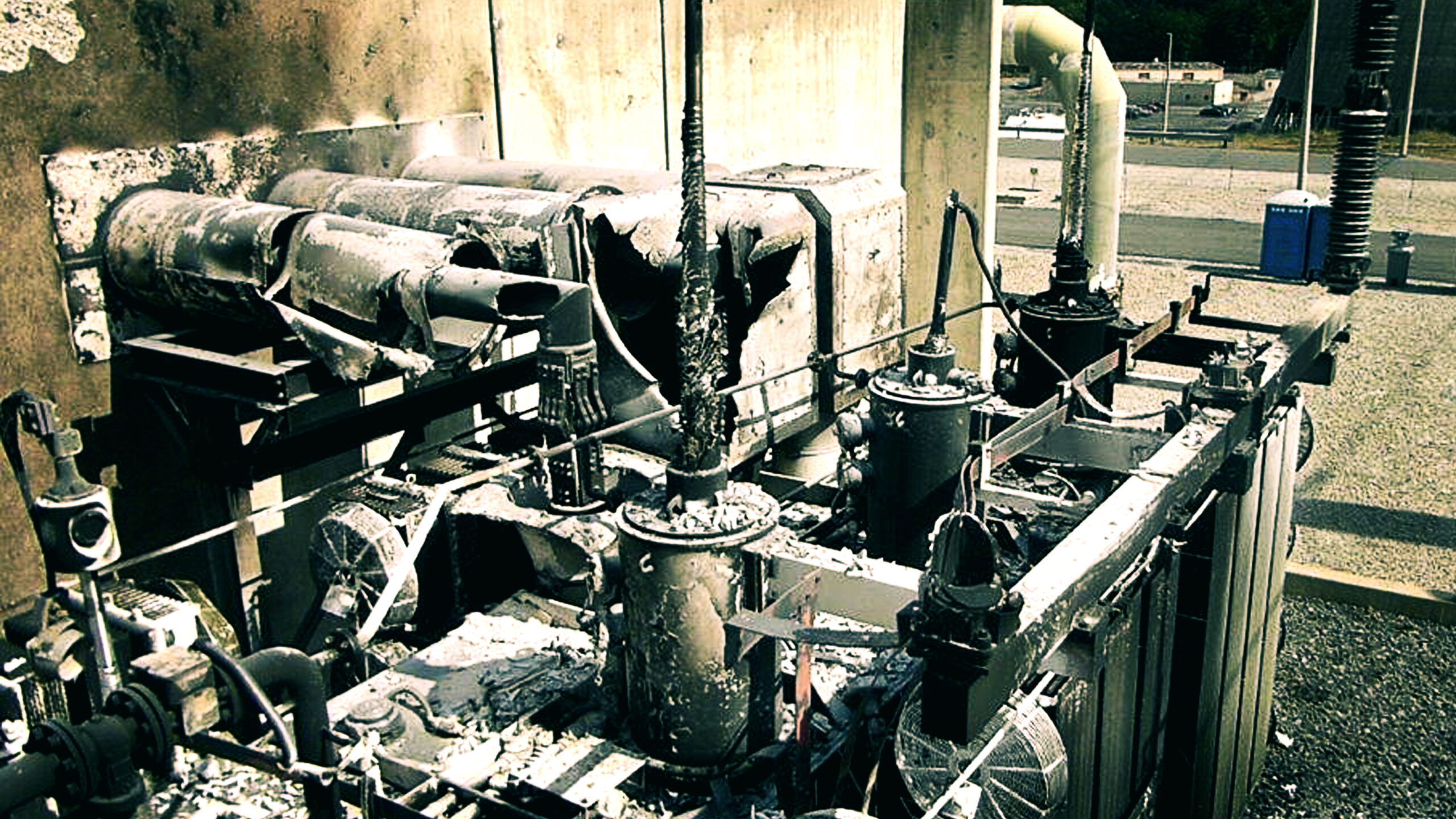

Most of us know what happens when a catastrophic event occurs at a transformer; power distribution comes to a grinding halt and plant personnel scramble into action to assess the damage and try to piece together the root cause in order to bring the system back to full operation as quickly as possible. However, what is almost always unexpected, is the logistics of replacing damaged electrical bus duct, an often-overlooked system critical component spanning from the generator to the main transformer, carrying the system’s full current. When a failure occurs, and the electrical bus duct is impacted, the entire energy producing system shuts down until the components and its appendices are repaired or replaced. The unplanned downtime often results in the revenue loss of hundreds of thousands of dollars while the plant isn’t generating power.